The mining consumable, Track Pins, were developed by Fortis Mining Engineering and Manufacturing to help assist undercutters at various mine sites.

Undercutters are used to cut the floor or wall in the mine to create a pathway so the ground is able to move. The Track Pin was created for the Under Cutter to ensure that it continuously operates effectively.

The Track Pin helps reduce the maintenance on mining Undercutters. Fortis Mining Engineering and Manufacturing's Track Pin is made with an alternative type of steel to safeguard it from breaking.

For more information on custom engineering, fabrication, and manufacturing contact us.

Phone: 306-242-4427

Email: sales@fortiscorporation.com

802, 57th Street East

Saskatoon, SK S7K 5Z1

Fortis Manufacturing and Engineering was contracted by Mosaic Colonsay to manufacture a custom Tool Skid.

Mosaic Colonsay requested a Tool Skid in order to store tools, parts, and slings. Using a Tool Skid for storing tools and parts is necessary because the Skid can be locked and secured to ensure that all equipment is accounted for.

What makes the Tool Skid unique is that it can be skidded around wherever it is needed and it can be secured and locked. The portability and locking mechanism allows for the Tool Skid to be easily utilized in numerous situations.

Tool Skids can be used in a variety of industries, jobs, or locations including construction and mining sites. The custom specifications including the storage, skid, and locking mechanism can accommodate all sizes of skids.

Mosaic Colonsay was very satisfied with the work completed by Fortis Mining Engineering and Manufacturing. For more information about Tool Skids or custom manufacturing, please contact us.

Contact Fortis Mining Engineering & Manufacturing

Phone: 306-242-4427

Email: sales@fortiscorporation.com

802, 57 Street East

Saskatoon, SK S7K 5Z1

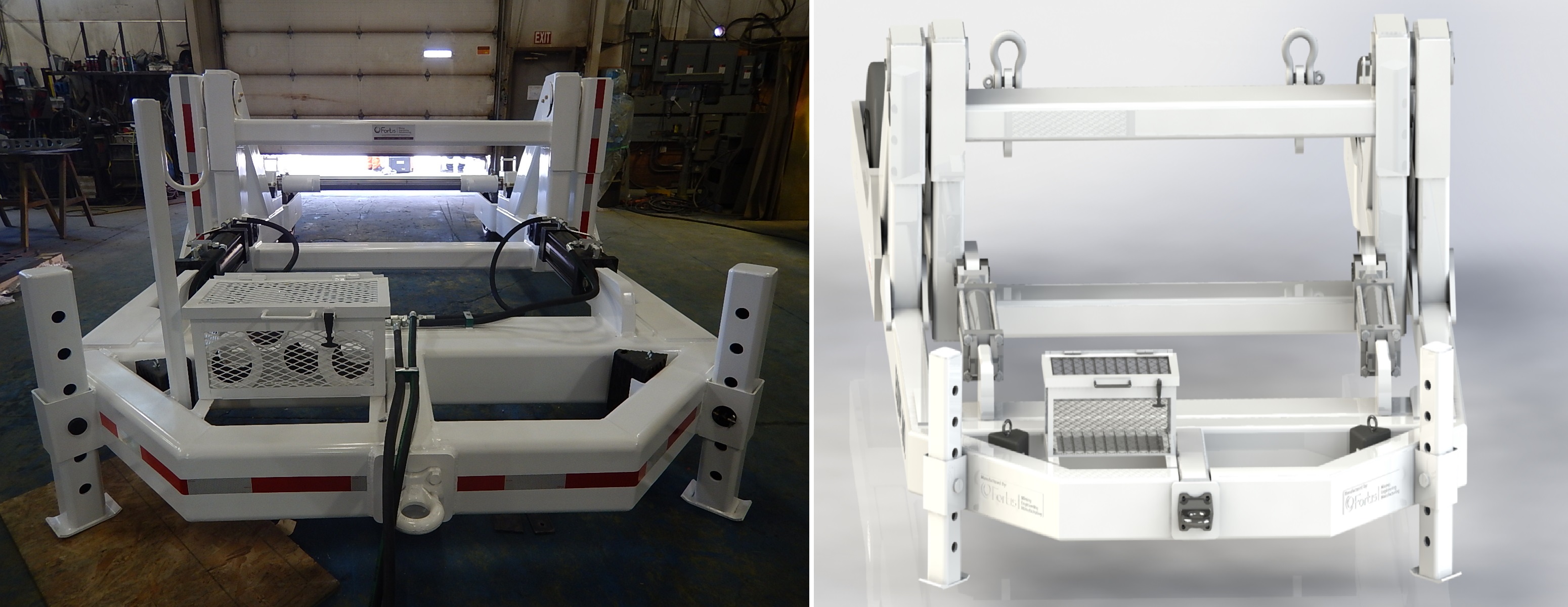

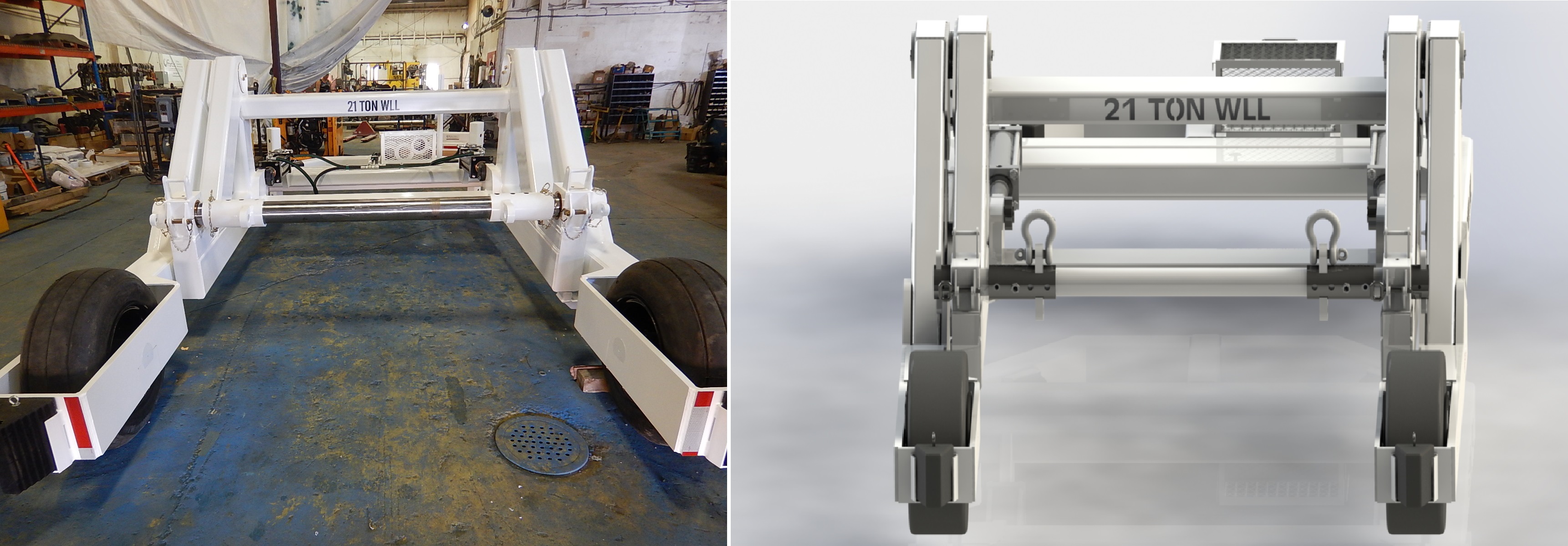

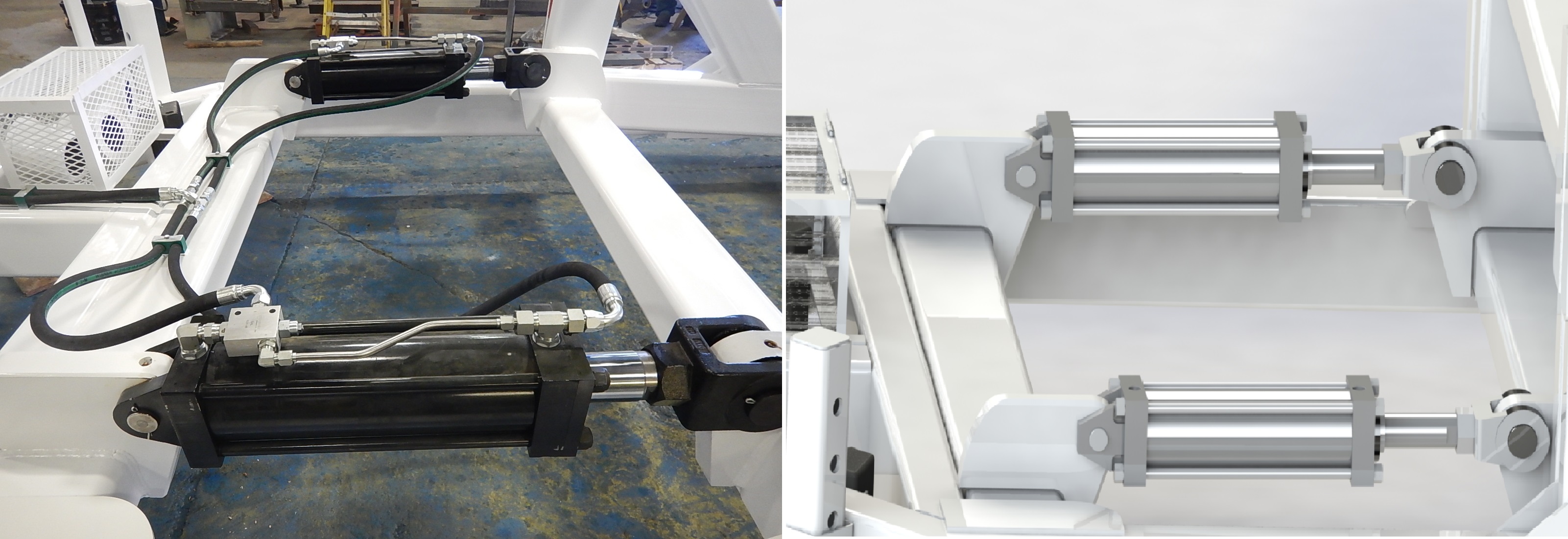

Fortis Mining Engineering and Manufacturing recently completed a job that required both engineering, manufacturing, and fabrication services. Searching for an efficient and safer alternative to transport reels, Fortis Mining Engineering and Manufacturing was tasked with creating a Reel Winder Trailer to fit specific client needs.

There are many unique specifications that the client required Fortis Mining Engineering and Manufacturing to adhere to to ensure the success of the Reel Winder Trailer.

The location that the reels were to be moved is very narrow. Therefore, the Reel Winder Trailer had to be engineered to move through this space, while still allowing for the pick up of different sizes of reels from diameter to width.

The engineered Reel Winder Trailer is narrow and capable of picking up various sizes of reels up to a maximum capacity of 21 tons using hydraulic auxiliary outlets.

Wire rope, plastic, pipe, and numerous other products that come on a reel can be transported using the Reel Winder Trailer. Fortis Mining Engineering and Manufacturing was able to successfully meet the client's specific and unique needs in order to provide a superior solution for reel transport.

For more information on custom solutions and services, please contact Fortis Mining Engineering and Manufacturing.

Phone: (306) 242-4427

Toll Free: (844) 542-2247

Email: info@fortiscorporation.com

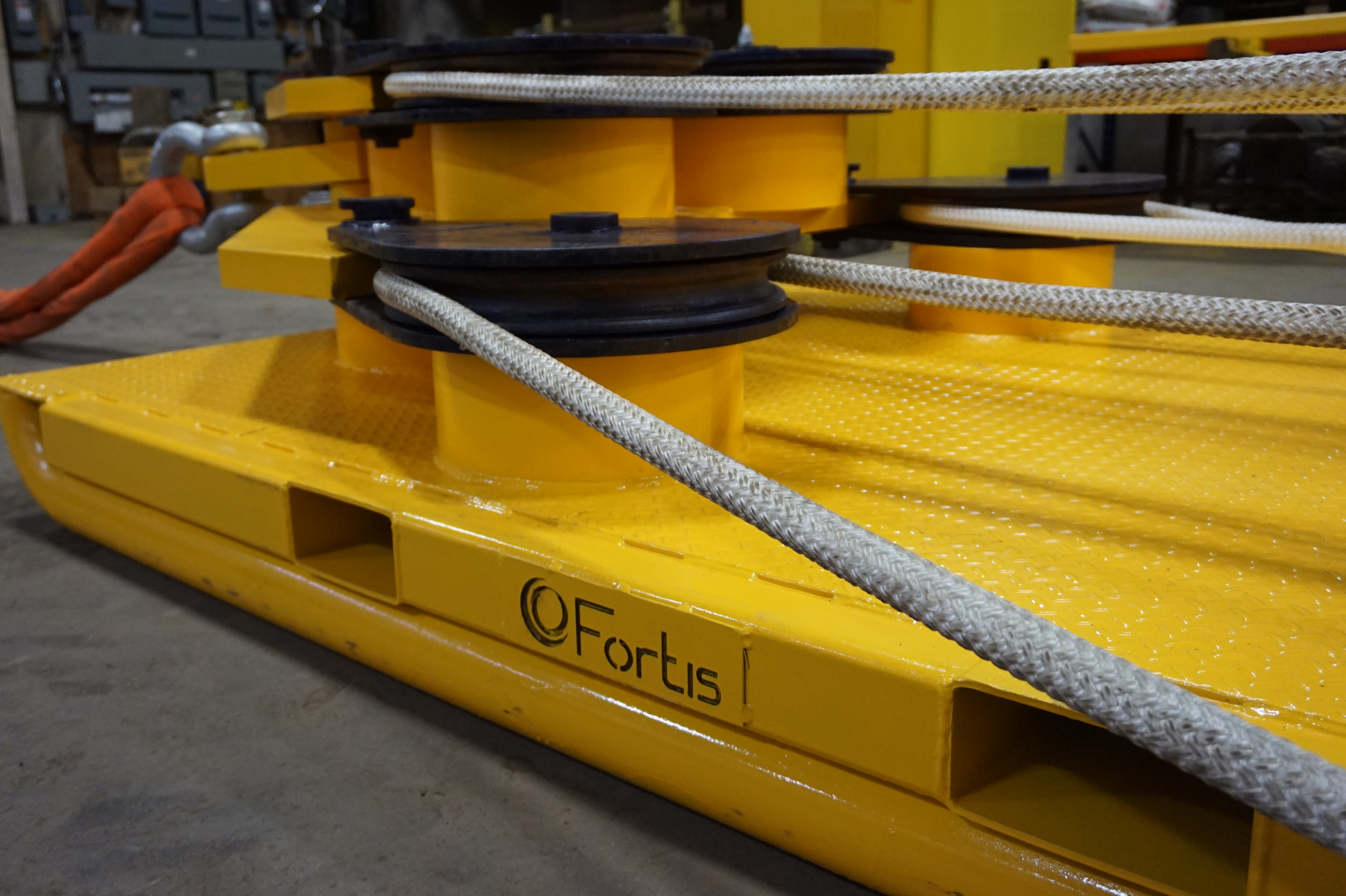

Designed by Fortis, the Retrieval Skid Platform was created with a series of snatch blocks for the retrieval of heavy equipment including Scoop Trams and other various machines in underground conditions where the drift or passage has collapsed and machine is unable to drive out with its own power. The Skid Platform is designed to increase the power output by a factor of 8 and decrease the pull speed by the same factor of 8. The Retrieval Skid Platform successfully extracted a scoop out of a drift at a Northern Cameco Uranium mine. The previous method of extractions would have typically involved bolting d-plates to the wall. The Retrieval Skid Platform increases the safety of equipment retrieval and has low failure rates.