Fortis is renowned world wide as an expert in mine hoist roping and conveyances. you can expect Fortis to offer every service, including procedure development and consulting.

Mine procedure development for:

- Mine Hoist Conveyance Replacement

- Mine Hoist Rope Change and Rope-Up

- Preventative Maintenance Planning

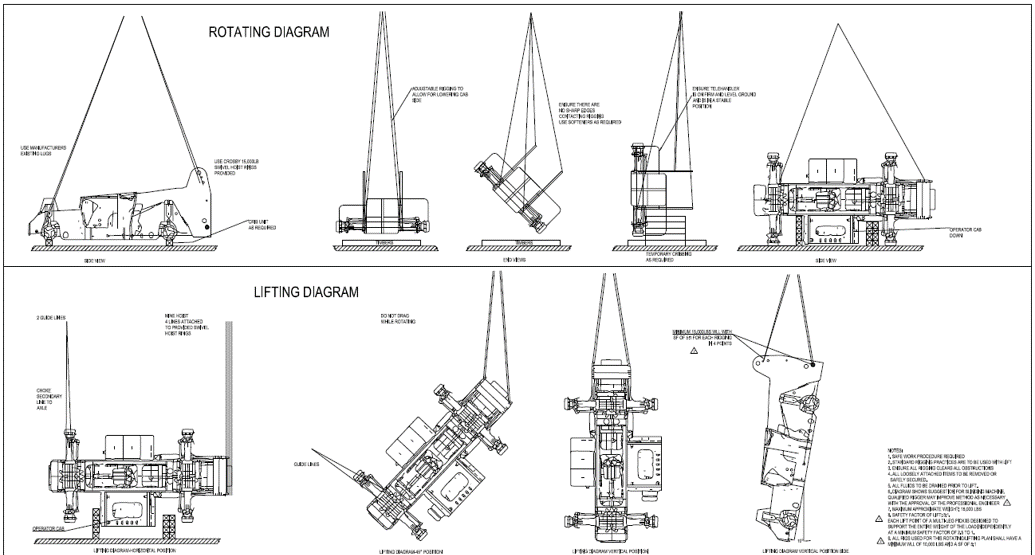

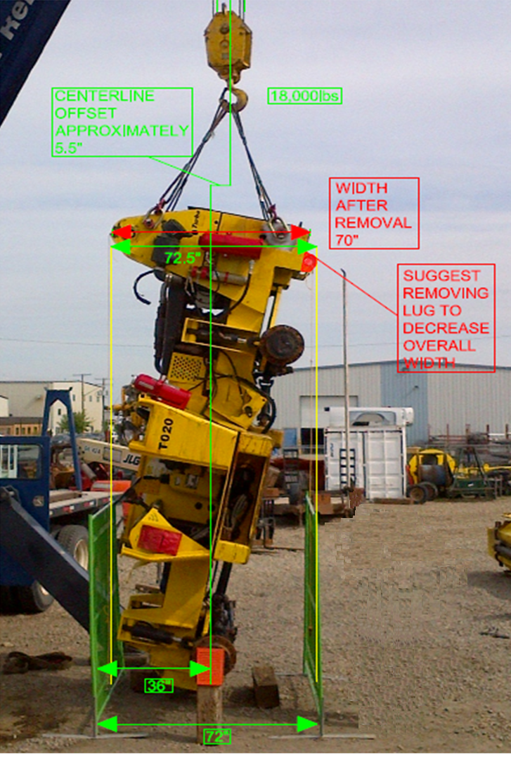

- Engineered Lift Plan Development

Fortis excels at shaft rope-up procedure development. Fortis recently created a rope up procedure for a competitive bid and execution for a client. The procedure included: Equipment selection, rope up methodology, safe work procedures, preliminary schedule, budgetary cost estimate, and pre-work / commissioning requirements were all included in the procedure.

Fortis recently created a Guide Rope Replacement procedure for a client overseas. We traveled to site, completed an assessment and a walk-through, and developed a detailed guide rope replacement procedure. The procedure included equipment requirements, procedure steps, sequence sketches, and safe work procedures.

We work with companies all over the world on mining procedures. If you would like further information about our services please contact us.

Phone: (306) 242-4427

Email: info@fortiscorporation.com

Fortis Mining Engineering and Manufacturing has an abundance of experience in providing lift studies and engineered lift plans for the Potash Mines of Saskatchewan with recent experience including development of lowering procedures with Blair Hoists and Sinking Winches.

Fortis has also developed a test lifting criteria for components which confirms that each piece of equipment hangs as per design within the individual shaft parameters which virtually eliminates rigging issues during shaft lowering.

Fortis rigging plans utilize our underground experience to maximize the capabilities of the shaft profile and hoist lifting capabilities.

Reduction in disassembly of equipment to get underground has saved client time and money.

Comprehensive lowering methodologies typically include a site specific material hoisting basket design that is compatible with the sinking arrangement if a cage is not available. This allows 'light loads' on pallets, bundles, or crates to be safely transported underground with speed and consistency.

Fortis is an industry leader in the development of critical lift plans for the mining and construction industries.