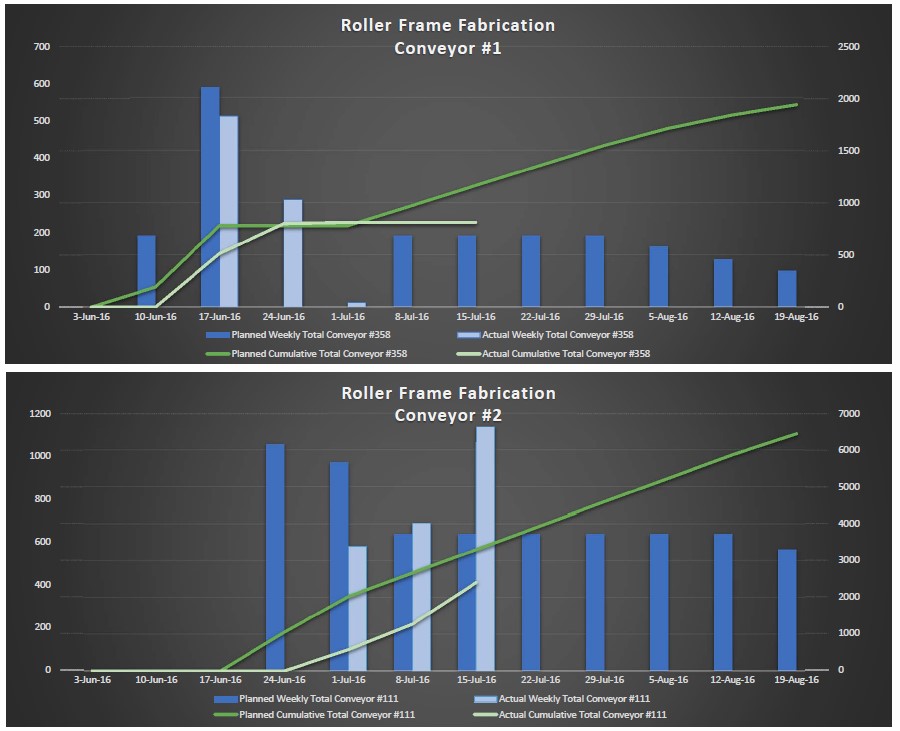

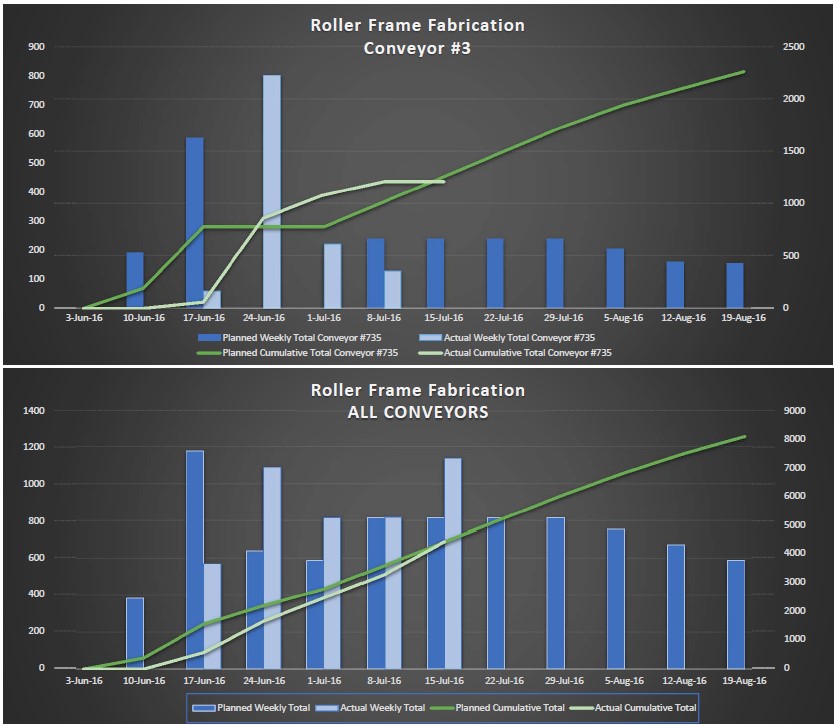

A few weeks ago we talked about how our fabrication shop is manufacturing a huge order of conveyor frames. Fortis managed to take control of the manufacturing side of the order, but how do we handle keeping our customer aware of where all the frames are?

Fortis is a multi-faceted organization with specialties ranging from manufacturing, to engineering, to project management, and site install when required. Fortis used all of these areas to bring together reporting metrics so our customer easily sees how the project is advancing at any stage of the project.

Fortis uses Earned Value Reporting to track progress and to provide updates to our customers. In the graphs below, Fortis uses this reporting method to establish trend lines showing how the brackets are progressing at weekly intervals. Our customer can see the status at a glance and can look at the detailed report as required.

There are three different types of frames required. Fortis tracks the progress on each frame and the whole order as a total. This allows Fortis to share with our customer the short falls and gains on an ongoing basis. This reporting eliminates surprises and allows Fortis to adjust the schedule and resources accordingly in order to ensure overall customer satisfaction.

As the frames are completed; labeling is attached as per our Clients requirements. Information including frame type, laydown areas (surface/underground), contact information, are just a few items we can include on the label. Fortis’ labels are waterproof to ensure the information won’t smudge or disappear when exposed to wet environments.

Fortis Mining, Engineering, and Manufacturing has the capability to fulfill all your Industrial needs. From engineering, to welding, to machining, to install, Fortis can complete all your project requirements. No job is too complex or too small, Fortis will work through them all.

Please visit www.fortiscorporation.com for a full company profile and please feel free to email info@fortiscorporation.com or call 306-242-4427 to contact Fortis to see how we can help you with your next project.

Fortis Mining Engineering and Manufacturing is proudly Saskatoon, Saskatchewan owned and operated.

It’s everybody’s favorite question and no one’s favorite game. Too many times we are expected to do something and if it’s done incorrectly, whether it be the front lines, side lines, or behind the lines, everyone finds someone to blame.

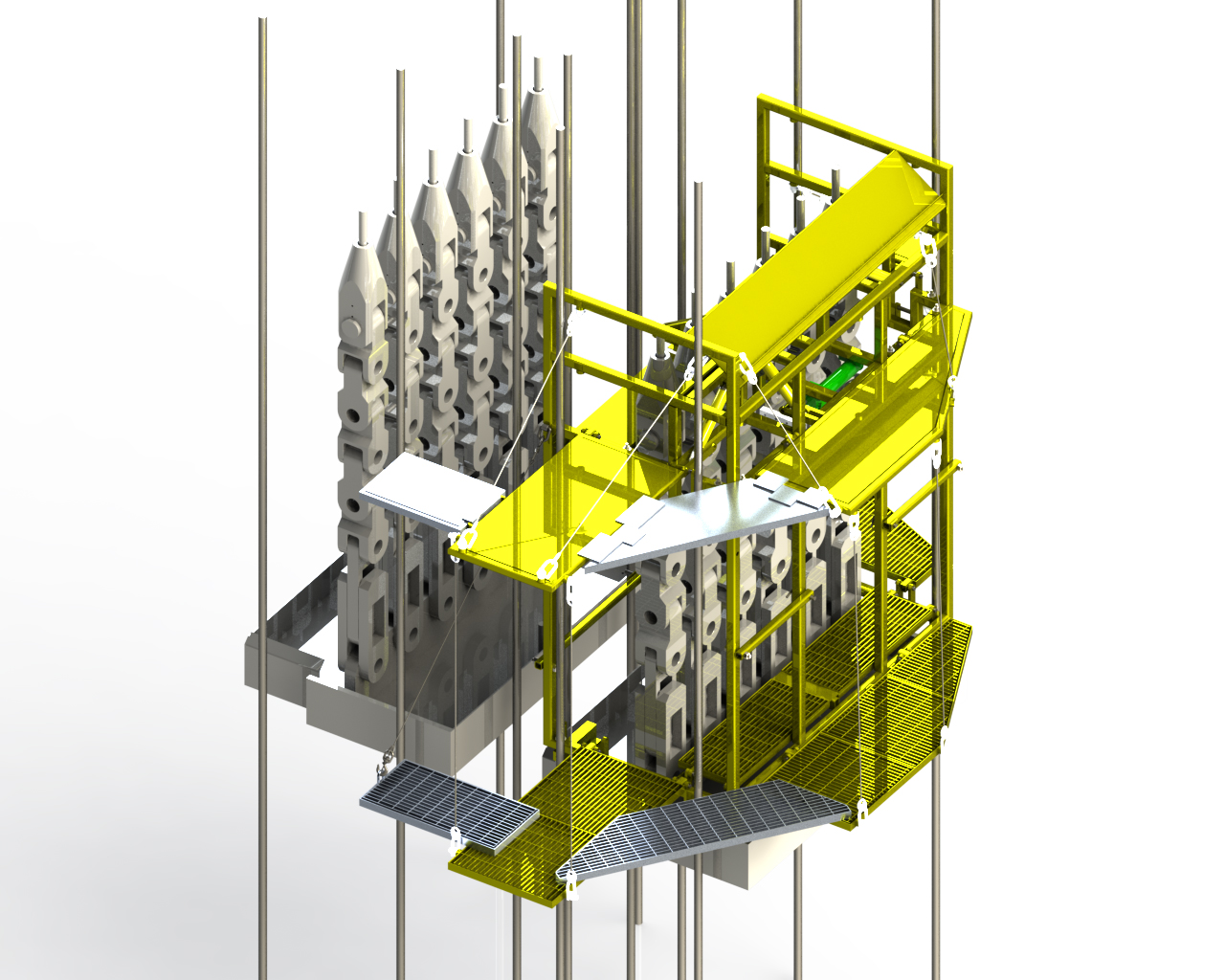

Recently, Fortis was asked to design a lifting device and as with nearly every product that gets designed there are many different stakeholders involved. There are people who request the products, who design the products, and who purchase and fabricate the products. As a designer, it is important that I properly communicate with all of the people involved. Sometimes, this involves asking questions that I don’t even know exist; this can make it very difficult to receive proper information. If I don’t know what questions to ask, how can I ask them?

If I design something and it is not what someone else envisioned, am I to blame? What about the person who requested the product and when they received it, it looked completely different than what they saw in their mind? Or the person who designed it on paper when they quoted it? All of these people knew the product that was being ordered and saw different versions of it being designed. Does this make it wrong? Absolutely not. The best example of this is an optical illusion - is it a young woman looking away, or the face of an older woman? Everyone sees things differently.

Since the beginning of time, people have been communicating. When it isn’t with words, it is with gestures and body language. Now communication is becoming more popular through email and technology where we can receive important information that can be properly tracked. This makes it easier to blame others because now we have proof of communication (or lack of). However, if no one is wrong, how can you place blame?

In the end, the importance of an issue should not be blaming someone for a “mistake” or seeing something differently – it should be determining how to resolve these issues so they don’t happen again. The only way to minimize issues is by providing any and all information on a specific vision for a product. Fortis Mining, Engineering, and Manufacturing excels at providing custom products for many different aspects of mining, manufacturing, and industrial solutions. We are always striving to improve communication internally (between Fortis Employees and Employers) and externally (between Fortis and its Customers). If you have a design in mind, it can be achieved at Fortis Mining, Engineering, and Manufacturing.

In the custom fabrication world most projects come and go however, every now and again there is a unique challenge to get a quality product efficiently completed in order to meet schedule requirements. While considering all aspects at hand and meeting quality control check points, Fortis Manufacturing has risen to the challenge repeatedly throughout its history.

The latest challenge currently being completed at Fortis’ fabrication shop, is a huge conveyor frames order – slightly over 8,100 of them. With Fortis Manufacturing ingenuity, the welding assembly line was born. In order to meet schedule requirements, each process and step needed to be identified and planned in order to ensure efficiency was a key factor.

When you think of a quick turn-around most people think that means rushing. When you rush shortcuts and corners being cut are inevitable in order to maintain the capacity to meet schedule requirements. And the truth is, there are! Fortis takes the following short-cuts to improve efficiency:

- Fortis short-cut the time needed to find parts – everything is in hand reach for fabrication.

- Fortis short-cut the set up time by building fixtures to aid in the welding.

- Fortis short-cut the time for moving welded components – Work areas were identified and staged to keep productivity levels at acceptable speeds.

- Fortis short-cut rework requirements by establishing continuous checks throughout the fabrication cycle.

With all these shortcuts certainly other areas will suffer? Actually, by identifying and planning the work for these frames, Fortis is also accomplishes the following:

- All the clients’ specifications are being met.

- Detailed inspection test plans are developed and being used to ensure all areas are being monitored and reviewed.

- Safety in design options offered to the Client for approval to highlight safety areas.

- Developing a value added packaging option, which can reduce waste as well as increase operation efficiency with moving a large volume of product.

- Ensuring all industry regulations and requirements are upheld like CWB certifications and industry requirements.

Fortis Mining, Engineering, and Manufacturing has the capability to fulfill all your Industrial needs. From engineering, to welding, to machining, to install, Fortis can complete all your project requirements. No job is too complex or too small, Fortis will work through them all.

Please visit www.fortiscorporation.com for a full company profile and please feel free to email info@fortiscorporation.com or call 306-242-4427 to contact Fortis to see how we can help you with you next project.

Fortis MIning, Engineering and Manufacturing is proudly Saskatoon, Saskatchewan owned and operated.

In April of 2015 Fortis received a failed balderson hitch for scoop tram attachment from Agrium Potash mine. We were tasked with fabricating a replacement balderson hitch for scoop tram. Not only did we deliver the fabricated and machined part on time, but we included a custom engineering design betterment which will improve reliability and reduce life cycle costs. We then followed up to ensure all was well after shipping the product back to site. This is what Agrium had to say when we followed up with them, "We just put one on yesterday and we did not even need butter to slide it into place. It was perfect!" What a great testimonial from Agrium on the excellent work our machine shop and welding shop competed!

Here is a picture of the balderson hitch Fortis fabricated:

Facts: Did you know that the Fortis welding shop is CWB certified?

Fortis Mining Engineering and Manufacturing is proudly Saskatoon, Saskatchewan owned and operated.

You start your day and everything seems to be as normal as it gets. Operations are running perfectly, all projects are running smoothly and are meeting schedule requirements. Out of left field comes a fly ball that hits you right between the eyes, a major upset that will has potential for a production loss, or missed deadlines. You have people you can rely on to help you through these situations, but everybody is busy so something has to move, or does it?

Being straddled with situations like the ones above seems to be more normal than not in our hectic schedules. How can you resolve the situation like the one above, do you panic? Or do you have a sound support team that can you get you through this? This is where a Fortis Engineering can assist you on-site, off-site, or take over certain areas of the problem completely. Fortis is an Engineering, Manufacturing and Mining service company based out of Saskatoon. Fortis Engineering can assist with all your technical support requirements throughout your operational activities or projects.

Fortis Engineering is skilled and ready to help in the following areas:

- Engineered Lift Plans and Rigging Studies.

- Engineered Lift plans for transportation through mine site shafts.

- Certified critical lift planning and staging requirements.

- Structural bearing beam supports for roping and de-roping of mine shafts.

- Skip, Cage, Lifting bale removal and install.

- Structural Design and Detailing.

- Custom design and drafting for jib cranes, monorails, and gantry cranes.

- Structural Galloway designs.

- Overhead protection and head covers for work in the shaft.

- Work decks and Inspection decks for working of the top of skips including head covers.

- Mechanical Design and Detailing

- Under the hook lifting devices including spreader bars and lifting beams

- Man baskets which are forklift-able or suspended from a crane

- Man baskets for shaft repair work meeting mine regulations requirements

- Concrete bucket and transportation systems

- Emergency egress shaft conveyance plans

- Engineering and drawings or electrical feeder cable installation for underground use

- Custom equipment designs

- Onsite engineering and design support available to handle complex mechanical and structural projects.

- Can provide project engineering and project design personnel onsite, to handle a project from start to finish.

Fortis Engineering can also take this one step further. With every engineered design produced, Fortis has the capability to manufacture and install everything that we design through Fortis’ manufacturing and mining divisions.

Please contact engineering@fortiscorporation.com for all your engineering and design requirements.

Work Deck With Headcover designed by Fortis