Fortis Mining Engineering and Manufacturing offers a wide range of services, including a full service CNC Machine Shop. The Fortis Machine shop is driven by quality; Fortis has highly skilled and experienced Journey persons and machinists that create custom machined and rebuilt products.

Fortis Commercial Machining services include machining steel, iron, brass, bronze, stainless, and plastics. Fortis also offers a diverse range of inventory sizes in 4140, 1018, and aluminum to ensure quick deliveries. The shop is responsible for fabricating all Mining Attachments for Northern Strands.

Further information about attachments available can be found here: https://www.northernstrands.com/attachments.aspx

The Fortis Machine Shop capabilities includes:

Lathes Swing Diameter Up to 22' (560 mm)

Distance between centers Up to 80' (200 mm)

Vertical Matching Centers X x Y x Z Up to 40" x 20" x 28"

Up to 1,000 mm x 500 mm x 700 mm

CNC Band Saw Max Cutting (round or square) 12" (300 mm)

Max Cutting (rectangle) 12" x 16" (300 mm x 400 mm)

Along with the Machine Shop capabilities, Fortis Mining Engineering and Manufacturing also has a a CWB Welding Certified Fabrication Shop. The Fortis commercial and industrial welding shop offers excellent quality products with a team of CWB Certified Journeyperson welders and fabricators.

The Commercial Fabrication shop is capable of fabricating all customer requests and is able to provide custom fabrication with backup from engineers, machinists, and pull testing departments. Fortis is CWB Certified in steel and has 3 level 1 weld inspectors.

Fortis has completed work for the mining industry, agricultural industries, construction industries. Jobs have also been completed for large companies including Nutrien, BHP, K+S, Mosaic, and many more.

For additional information on all of Fortis' services & capabilities, click the following:

Contact Fortis Mining Engineering Manufacturing

802, 57th Street East

Saskatoon, SK S7K 5Z1

Hours of Operation: 7:30am to 5:00pm Mon – Fri

Fax: (306) 242-3713

Request for Quotation:

Request for Proposal:

Sales (Customer Purchase Orders):

The mining consumable, Track Pins, were developed by Fortis Mining Engineering and Manufacturing to help assist undercutters at various mine sites.

Undercutters are used to cut the floor or wall in the mine to create a pathway so the ground is able to move. The Track Pin was created for the Under Cutter to ensure that it continuously operates effectively.

The Track Pin helps reduce the maintenance on mining Undercutters. Fortis Mining Engineering and Manufacturing's Track Pin is made with an alternative type of steel to safeguard it from breaking.

For more information on custom engineering, fabrication, and manufacturing contact us.

Phone: 306-242-4427

Email: sales@fortiscorporation.com

802, 57th Street East

Saskatoon, SK S7K 5Z1

Fortis Manufacturing and Engineering was contracted by Mosaic Colonsay to manufacture a custom Tool Skid.

Mosaic Colonsay requested a Tool Skid in order to store tools, parts, and slings. Using a Tool Skid for storing tools and parts is necessary because the Skid can be locked and secured to ensure that all equipment is accounted for.

What makes the Tool Skid unique is that it can be skidded around wherever it is needed and it can be secured and locked. The portability and locking mechanism allows for the Tool Skid to be easily utilized in numerous situations.

Tool Skids can be used in a variety of industries, jobs, or locations including construction and mining sites. The custom specifications including the storage, skid, and locking mechanism can accommodate all sizes of skids.

Mosaic Colonsay was very satisfied with the work completed by Fortis Mining Engineering and Manufacturing. For more information about Tool Skids or custom manufacturing, please contact us.

Contact Fortis Mining Engineering & Manufacturing

Phone: 306-242-4427

Email: sales@fortiscorporation.com

802, 57 Street East

Saskatoon, SK S7K 5Z1

Fortis Engineering & Manufacturing Inc. has successfully been audited by an expert third party certifier for ISO Quality Management System (QMS) and is pleased to announce that it meets all the requirements of ISO 9001:2015, ISO 14001-2016, and ISO 45001-2018 and are certified to these Standards.ISO 45001-2018

- A new International Standards (formally OHSAS 18001) that specifies requirements for an Occupational Health and Safety (OH&S) management system, to enable Fortis to proactively improve OH&S performance in preventing injury and ill-health. Fortis is one of the first companies in Canada to achieve this Standard

ISO 45001-18 demonstrates that Fortis is committed to improve OH&S performance by:

- Developing and implementing an OH&S policy and OH&S objectives

- Establishing systematic processes which consider its "context" and which consider its risks and opportunities, legal, and other requirements

- Determining the hazards and OH&S risks associated with its activities; seeking to eliminate them, or putting in controls to minimize their potential effects

- Establishing operational controls to manage its OH&S risks and its legal and other requirements

ISO 9001-2015ISO 9001-15 demonstrates that Fortis is committed to:

- Total quality management

- Customer focus

- A continuous improvement process approach implemented throughout the organization

- Critical processes and their interactions are understood and documented

- A strong management commitment to all these facets of the ISO 9001

- Integrating Risk Management into all aspects of the business

ISO 14001-2016- Environmental Management System (EMS) is a systematic framework to manage the immediate and long-term environmental impacts of Fortis' products, services, and processes. Through Certification in this Standard, Fortis can assure stakeholders that our environmental management system meets international industry specific environmental standards.

ISO 14001-2016 demonstrates that Fortis is committed to:

- Minimize the environmental footprint

- Diminish the risk of pollution incidents

- Provide operational improvements

- Ensure compliance with relevant environmental legislation

- Develop their business in a sustainable manner

- Identify cost savings with greater emphasis on resource, waste, and energy management

- Increasing awareness of OH&S risks

- Evaluating its OH&S performance and seeking to improve it, by taking appropriate actions

- Ensuring workers take an active role in OH&S matters

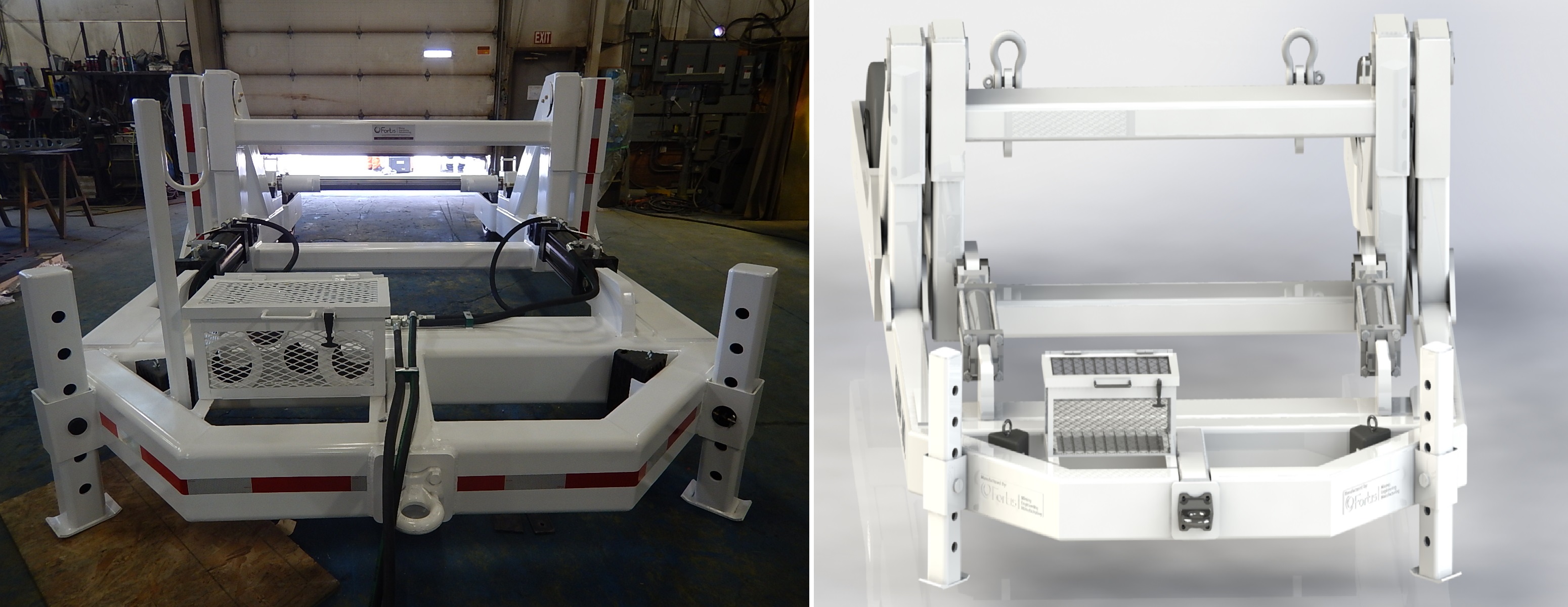

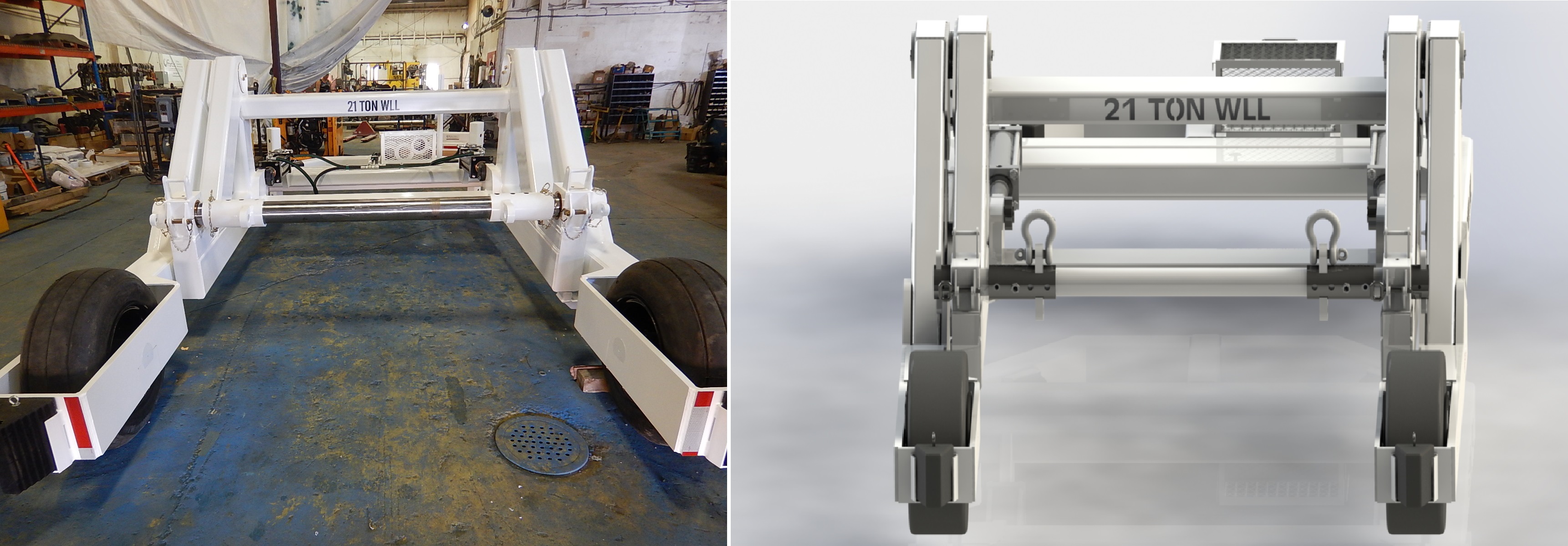

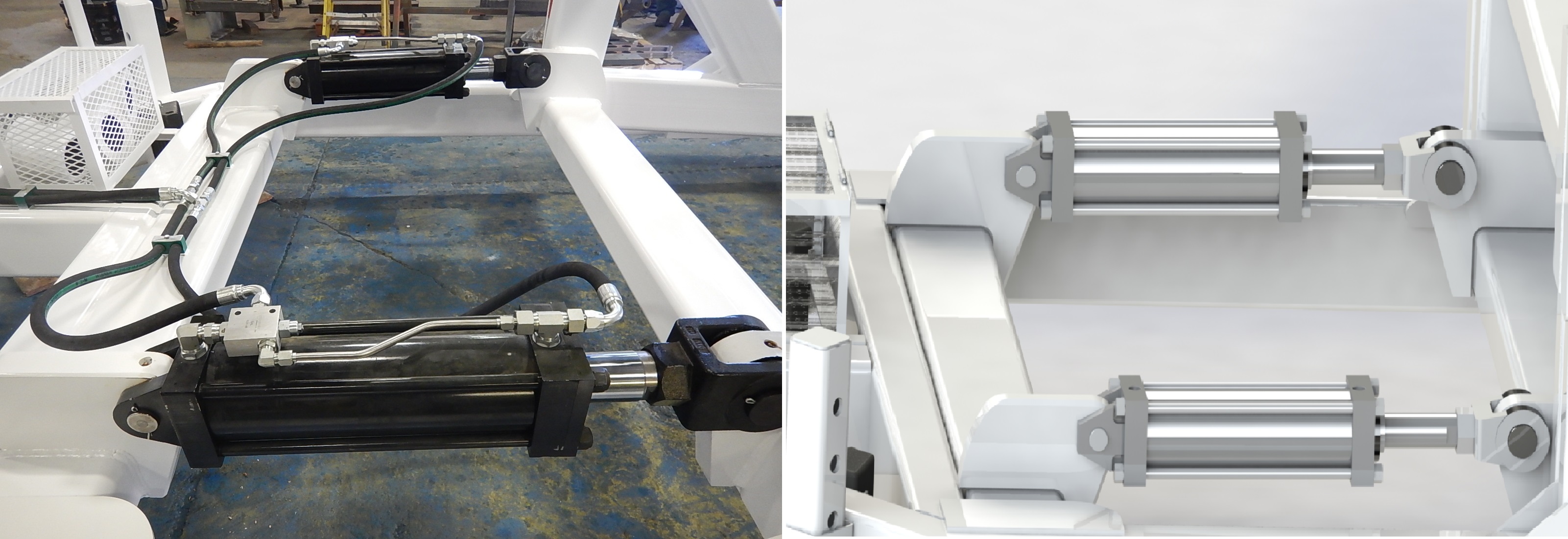

Fortis Mining Engineering and Manufacturing recently completed a job that required both engineering, manufacturing, and fabrication services. Searching for an efficient and safer alternative to transport reels, Fortis Mining Engineering and Manufacturing was tasked with creating a Reel Winder Trailer to fit specific client needs.

There are many unique specifications that the client required Fortis Mining Engineering and Manufacturing to adhere to to ensure the success of the Reel Winder Trailer.

The location that the reels were to be moved is very narrow. Therefore, the Reel Winder Trailer had to be engineered to move through this space, while still allowing for the pick up of different sizes of reels from diameter to width.

The engineered Reel Winder Trailer is narrow and capable of picking up various sizes of reels up to a maximum capacity of 21 tons using hydraulic auxiliary outlets.

Wire rope, plastic, pipe, and numerous other products that come on a reel can be transported using the Reel Winder Trailer. Fortis Mining Engineering and Manufacturing was able to successfully meet the client's specific and unique needs in order to provide a superior solution for reel transport.

For more information on custom solutions and services, please contact Fortis Mining Engineering and Manufacturing.

Phone: (306) 242-4427

Toll Free: (844) 542-2247

Email: info@fortiscorporation.com