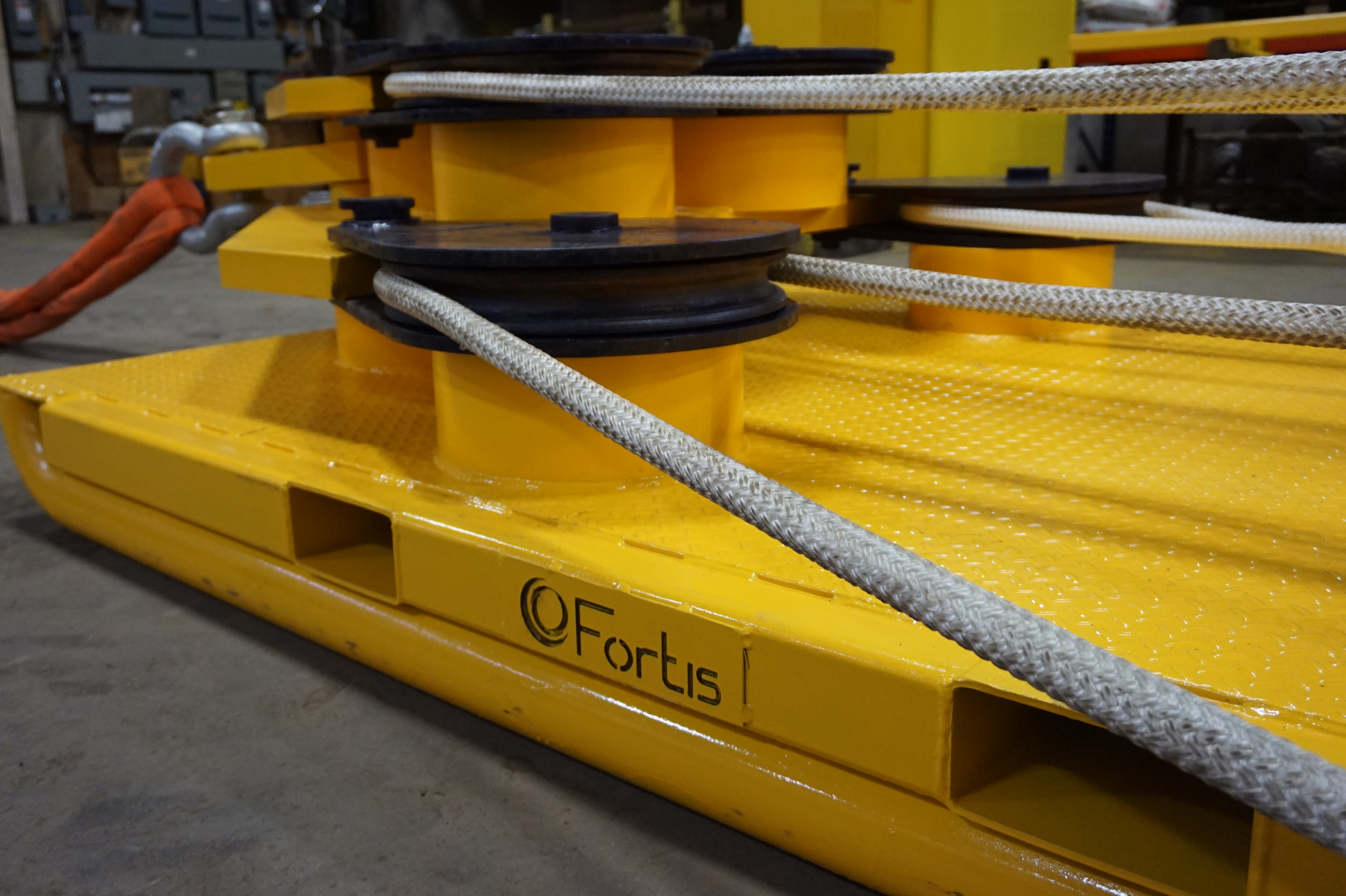

Designed by Fortis, the Retrieval Skid Platform was created with a series of snatch blocks for the retrieval of heavy equipment including Scoop Trams and other various machines in underground conditions where the drift or passage has collapsed and machine is unable to drive out with its own power. The Skid Platform is designed to increase the power output by a factor of 8 and decrease the pull speed by the same factor of 8. The Retrieval Skid Platform successfully extracted a scoop out of a drift at a Northern Cameco Uranium mine. The previous method of extractions would have typically involved bolting d-plates to the wall. The Retrieval Skid Platform increases the safety of equipment retrieval and has low failure rates.

Fortis Mining, Engineering &

Manufacturing was recently contracted by SaskPower to complete a comprehensive

Lifting Lug & Monorail Remediation project at the Shand Power Station. The project

consisted of multiple components including: 1) inspecting, load testing and

certifying existing lifting lugs and monorails within the plant to bring them

to current client and occupational health and safety standards; 2) adding or

modifying supporting structural steel to existing lifting lugs and monorails

followed by the load testing and certification of the device; and 3)

Installation of new lifting devices and monorails including all supporting

structural steel installations, load testing and certifying of the new lifting

devices. The total project consisted of

244 items including 219 Lifting Lugs and 25 Monorails. This included 18 New

Lifting Lug Installations, the inspection and testing of 184 existing lugs, the

installation of 9 new monorails, and the inspection, testing, and painting of

15 existing monorails.

As part

of the project execution, Fortis was responsible for completing all structural

detailing, providing certified shop and erection drawings, fabrication of all

structural steel, installation of all structural steel and lifting devices,

load testing of all components, and generating test reports and turnover

documentation for the client. Fortis also designed and fabricated custom sized

weld and bolt-on lifting lugs in-house for the project to suit applicable site

standards and colour coding.

To

ensure quality of products provided an Inspection Test Plan was developed to

ensure compliance to applicable standards and specifications. Fortis also

developed a comprehensive digital and physical turnover package including all

relevant company and personnel certifications, project registers, executed ITP

and check sheets, as-built/redline drawings, procedures and manuals, and all

other quality documentation compiled.

Fortis

Mining Engineering and Manufacturing has achieved and maintained ISO 9001

Quality Management, 14001 Environmental Management and OHSAS 18001 Health &

Safety Management Certifications.

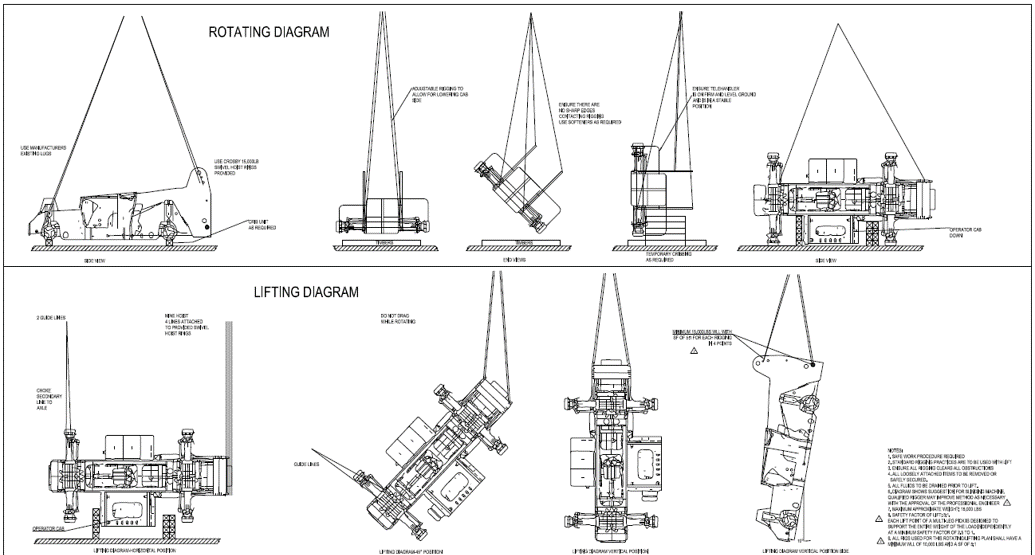

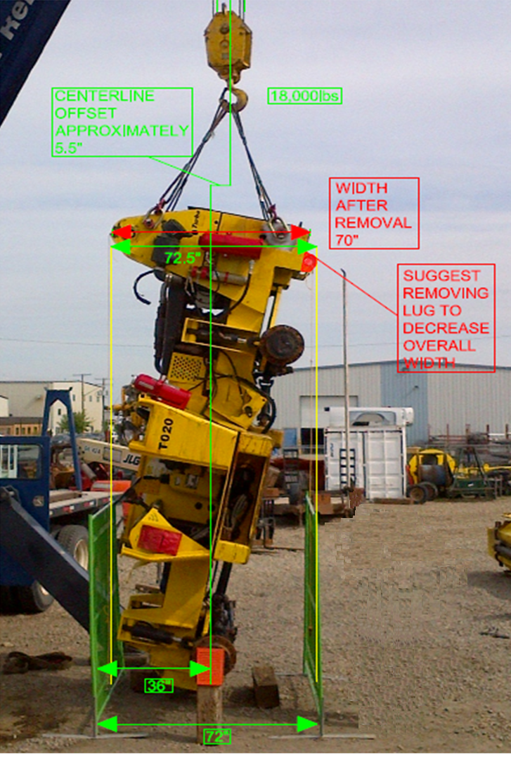

Fortis Mining Engineering and Manufacturing has an abundance of experience in providing lift studies and engineered lift plans for the Potash Mines of Saskatchewan with recent experience including development of lowering procedures with Blair Hoists and Sinking Winches.

Fortis has also developed a test lifting criteria for components which confirms that each piece of equipment hangs as per design within the individual shaft parameters which virtually eliminates rigging issues during shaft lowering.

Fortis rigging plans utilize our underground experience to maximize the capabilities of the shaft profile and hoist lifting capabilities.

Reduction in disassembly of equipment to get underground has saved client time and money.

Comprehensive lowering methodologies typically include a site specific material hoisting basket design that is compatible with the sinking arrangement if a cage is not available. This allows 'light loads' on pallets, bundles, or crates to be safely transported underground with speed and consistency.

Fortis is an industry leader in the development of critical lift plans for the mining and construction industries.

The sandblasting and painting team at Fortis Mining, Engineering, and Manufacturing do an amazing job restoring a rusted trailer under a tight schedule. From old to new in no time!

This trailer came in extremely rusty. It was then sandblasted to an SP-6 to clean any rust and paint off the surface. The trailer was blown down and prepped for paint.

The trailer was then sprayed with 3 mils of 2-part epoxy primer and left to cure for the full 24 hour cure time of the primer. Next the trailer went down the street to Polartech Sprayfoam to be bedlined at an average thickness of 40 mils. The complete refurbishment of the trailer was a 2 day process to limit the customers down time without the trailer.

Fortis Mining, Engineering, and Manufacturing has the full capabilities to refurbish(sandblast and paint) old equipment, trucks, trailers, steel, and concrete.

Sandblasting Capabilities:

- Mine Structural Steel, Product Bins, Concrete Refinishing

- Industrial Equipment

- Farm Equipment

- Truck Frame and Trailer Refurbishing

- Steel Preparation, Acid Etching, Abrasive Blasting

- Mobile Sandblasting and Painting

- Plus Much More

View our Sandblasting Services Brochure for more details http://www.fortiscorporation.com/pdf/sandblasting.pdf

Contact Fortis Mining, Engineering, and Manufacturing to inquire about our fabrication, machining, welding, painting, and sandblasting services.

Phone: (306) 242-4427

Toll Free: (844) 542-2247

Email: info@fortiscorporation.com

Website: http://fortiscorporation.com

Fortis Mining, Engineering, and Manufacturing is proudly Saskatoon, Saskatchewan owned and operated.

Fortis Mining, Engineering, and Manufacturing has the full capabilities to refurbish old equipment, trucks, trailers, steel and concrete. Recently Fortis refurbished bail and pods for PCS Cory. This included sand blasting and painting, replacing some structural steel, and machining new parts. This was all accomplished within 10 days.

Sandblasting Capabilities:

- Mine Structural Steel, Product Bins, Concrete Refinishing

- Industrial Equipment

- Farm Equipment

- Truck Frame and Trailer Refurbishing

- Steel Preparation, Acid Etching, Abrasive Blasting

- Mobile Sandblasting and Painting

- Plus much more

View our Sandblasting Services Brochure for more details http://www.fortiscorporation.com/pdf/sandblasting.pdf

Machining Capabilities:

- Machining Steel, Iron, Brass, Bronze, Stainless, Plastics, Aluminum

- Lathes

- Vertical Machining Centers

- CNC Band Saw

View all our Machining Capabilities at http://www.fortiscorporation.com/machining

Contact Fortis Mining, Engineering, and Manufacturing to inquire about our fabrication, machining, welding, painting and sandblasting services.

Phone: (306) 242-4427

Toll Free: (844) 542-2247

Email: info@fortiscorporation.com

Website: http://www.fortiscorporation.com/

Fortis Mining, Engineering, and Manufacturing is proudly Saskatoon, Saskatchewan owned and operated.