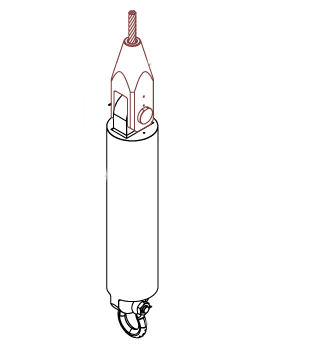

Fortis was contracted by Kibali Gold in the Democratic Republic of Congo to perform consulting and procedure work. The consultation resulted in a order to Northern Strands, Fortis' sister company, for a torpedo Counterweight. Fortis manufactured the torpedo for Northern Strands to sell to Kibali Gold. The purpose of the torpedo is to increase safety and the efficiency of the client's operations.

The Torpedo Counterweight is used as a rope end attachment, adding weight to end of a hoist or reeving rope. This helps to keep rolling back over a sheave in the headframe (or otherwise) if the rope weight from the hoist to the sheave exceeds the rope weight from the sheave down to the highest point you will need to hoist the rope end.

The Torpedo Counterweight is an engineered in-line counterweight that adds a lot of functionality and mitigates risks involved while doing rope work. The unit was pull tested (proof loaded) at 50,000 pounds, which is 2.5 times the working load limit. This test was completed in Fortis' horizontal test bed. The unit was then visually and non-destructively (mag-particle) tested following the proof loading.

Shipped in an International shipping container, the Torpedo Counterweight along with additional rigging products then left the Saskatoon Warehouse and travelled to Kibali Gold in the Democratic Republic of the Congo.

If your business needs consulting, procedure development, and manufacturing work completed, please contact us!

Fortis Mining Engineering Manufacturing

802, 57th Street East

Saskatoon, SK S7K 5Z

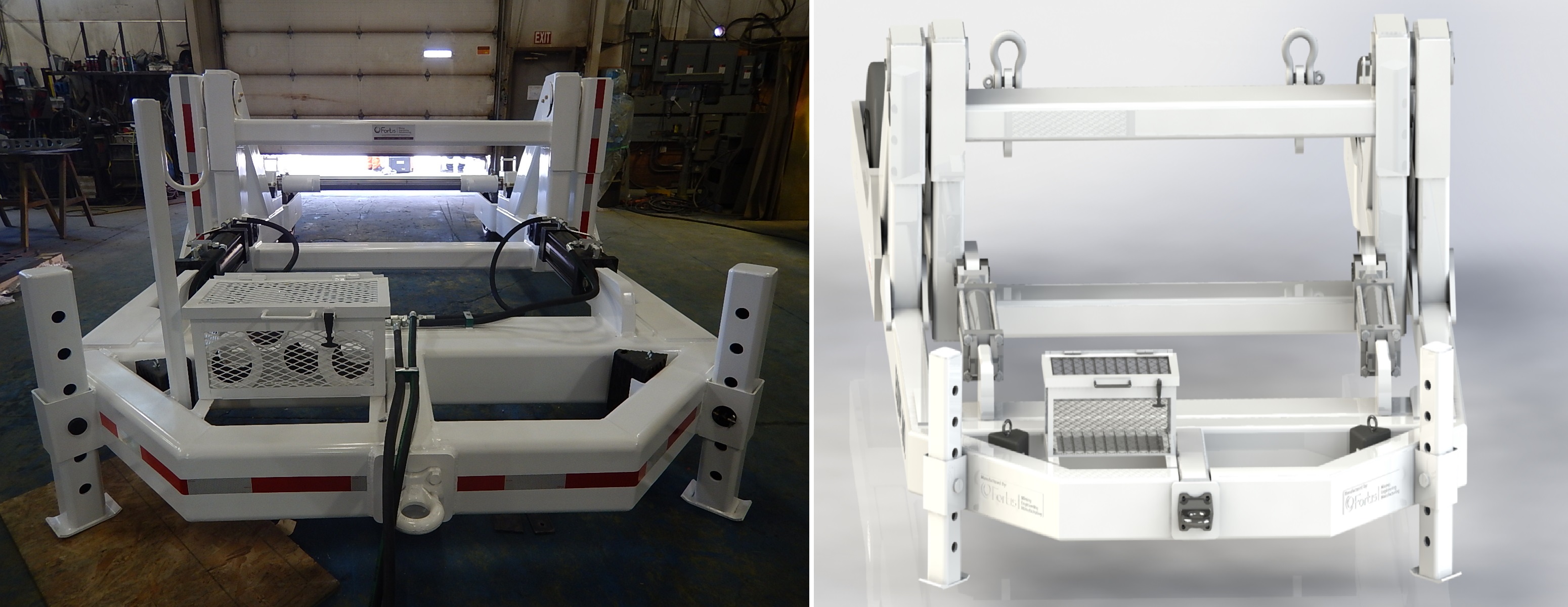

Fortis was recently contracted to manufactured a Mine Shaft Skip Dolly for Nutrien Allan. The skip is rested on the dolly and then is picked up at the other end using a loader to help with easy maneuvering when loading.

This Skip Dolly is site specific, but Fortis is able to manufacture and modify them for additional sites and uses.

This Skip Dolly was manufactured to replace an old non-engineered model.

Other examples of Fortis fabrication and engineering include:

- Jib cranes

- Spreader bars / lifting beams / lifting devices

- Monorails

- D-plates

- Deflection sheaves

- Reel unwinder

- Reel transportation trailers

- Explosive transporter

- Mobile reel handlers

- Material baskets

- Man baskets

- Electrical Cable Brackets

- Mine site shaft steel

- Concert buckets

- Working Platforms / Head covers

- Brine tanks

- Handrail

- Specialized products for mining industries

- Fall protection anchors

- Galloways

- Gin Cart

- Custom Mobile Reel handlers

- Explosives Cabinet

- Emergency Man Capsule

- Zim Car

- Reel Trailer

Contact Us

802, 57th Street East

Saskatoon, SK S7K 5Z1

Fortis Manufacturing and Engineering was contracted by Mosaic Colonsay to manufacture a custom Tool Skid.

Mosaic Colonsay requested a Tool Skid in order to store tools, parts, and slings. Using a Tool Skid for storing tools and parts is necessary because the Skid can be locked and secured to ensure that all equipment is accounted for.

What makes the Tool Skid unique is that it can be skidded around wherever it is needed and it can be secured and locked. The portability and locking mechanism allows for the Tool Skid to be easily utilized in numerous situations.

Tool Skids can be used in a variety of industries, jobs, or locations including construction and mining sites. The custom specifications including the storage, skid, and locking mechanism can accommodate all sizes of skids.

Mosaic Colonsay was very satisfied with the work completed by Fortis Mining Engineering and Manufacturing. For more information about Tool Skids or custom manufacturing, please contact us.

Contact Fortis Mining Engineering & Manufacturing

Phone: 306-242-4427

Email: sales@fortiscorporation.com

802, 57 Street East

Saskatoon, SK S7K 5Z1

Fortis Engineering & Manufacturing Inc. has successfully been audited by an expert third party certifier for ISO Quality Management System (QMS) and is pleased to announce that it meets all the requirements of ISO 9001:2015, ISO 14001-2016, and ISO 45001-2018 and are certified to these Standards.ISO 45001-2018

- A new International Standards (formally OHSAS 18001) that specifies requirements for an Occupational Health and Safety (OH&S) management system, to enable Fortis to proactively improve OH&S performance in preventing injury and ill-health. Fortis is one of the first companies in Canada to achieve this Standard

ISO 45001-18 demonstrates that Fortis is committed to improve OH&S performance by:

- Developing and implementing an OH&S policy and OH&S objectives

- Establishing systematic processes which consider its "context" and which consider its risks and opportunities, legal, and other requirements

- Determining the hazards and OH&S risks associated with its activities; seeking to eliminate them, or putting in controls to minimize their potential effects

- Establishing operational controls to manage its OH&S risks and its legal and other requirements

ISO 9001-2015ISO 9001-15 demonstrates that Fortis is committed to:

- Total quality management

- Customer focus

- A continuous improvement process approach implemented throughout the organization

- Critical processes and their interactions are understood and documented

- A strong management commitment to all these facets of the ISO 9001

- Integrating Risk Management into all aspects of the business

ISO 14001-2016- Environmental Management System (EMS) is a systematic framework to manage the immediate and long-term environmental impacts of Fortis' products, services, and processes. Through Certification in this Standard, Fortis can assure stakeholders that our environmental management system meets international industry specific environmental standards.

ISO 14001-2016 demonstrates that Fortis is committed to:

- Minimize the environmental footprint

- Diminish the risk of pollution incidents

- Provide operational improvements

- Ensure compliance with relevant environmental legislation

- Develop their business in a sustainable manner

- Identify cost savings with greater emphasis on resource, waste, and energy management

- Increasing awareness of OH&S risks

- Evaluating its OH&S performance and seeking to improve it, by taking appropriate actions

- Ensuring workers take an active role in OH&S matters

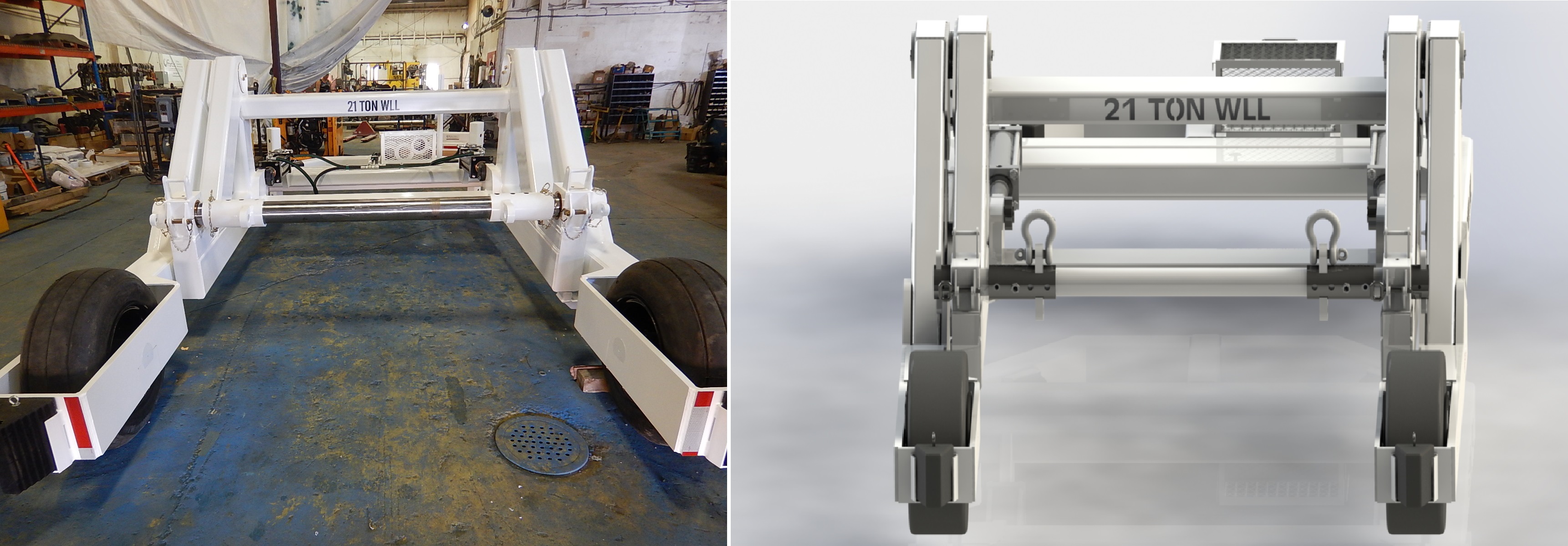

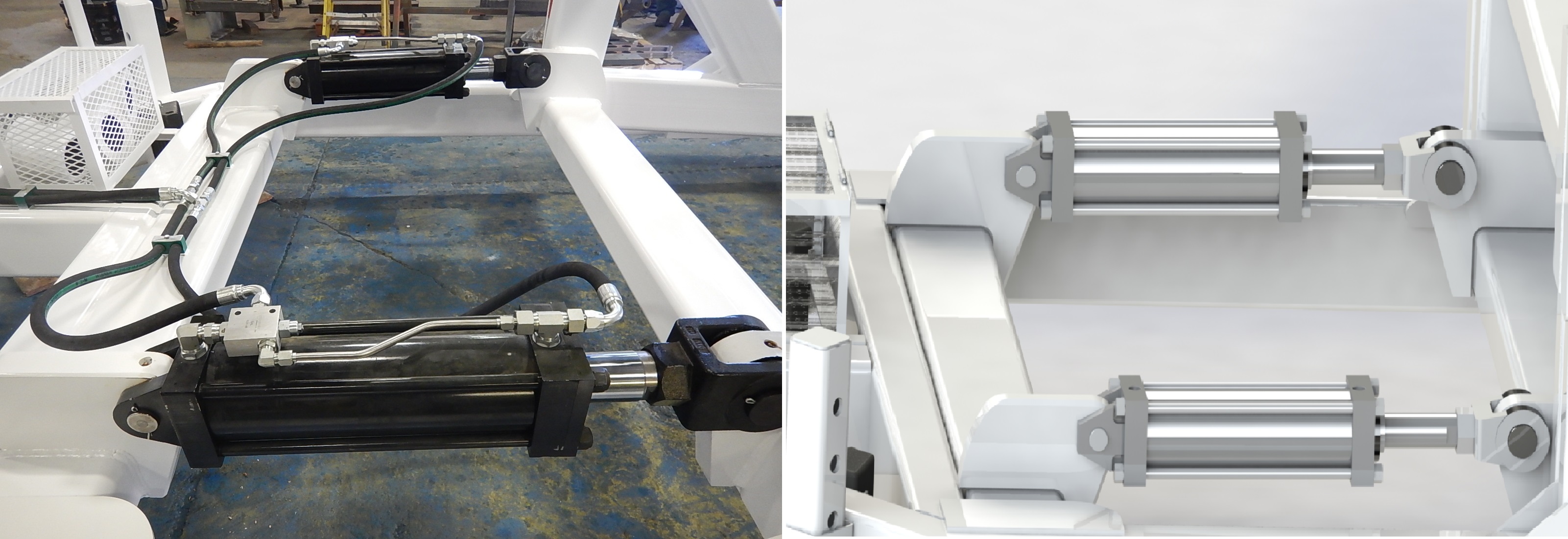

Fortis Mining Engineering and Manufacturing recently completed a job that required both engineering, manufacturing, and fabrication services. Searching for an efficient and safer alternative to transport reels, Fortis Mining Engineering and Manufacturing was tasked with creating a Reel Winder Trailer to fit specific client needs.

There are many unique specifications that the client required Fortis Mining Engineering and Manufacturing to adhere to to ensure the success of the Reel Winder Trailer.

The location that the reels were to be moved is very narrow. Therefore, the Reel Winder Trailer had to be engineered to move through this space, while still allowing for the pick up of different sizes of reels from diameter to width.

The engineered Reel Winder Trailer is narrow and capable of picking up various sizes of reels up to a maximum capacity of 21 tons using hydraulic auxiliary outlets.

Wire rope, plastic, pipe, and numerous other products that come on a reel can be transported using the Reel Winder Trailer. Fortis Mining Engineering and Manufacturing was able to successfully meet the client's specific and unique needs in order to provide a superior solution for reel transport.

For more information on custom solutions and services, please contact Fortis Mining Engineering and Manufacturing.

Phone: (306) 242-4427

Toll Free: (844) 542-2247

Email: info@fortiscorporation.com